Personalizing Home Décor with Self-Adhesive Vinyl Craft Sticker Rolls

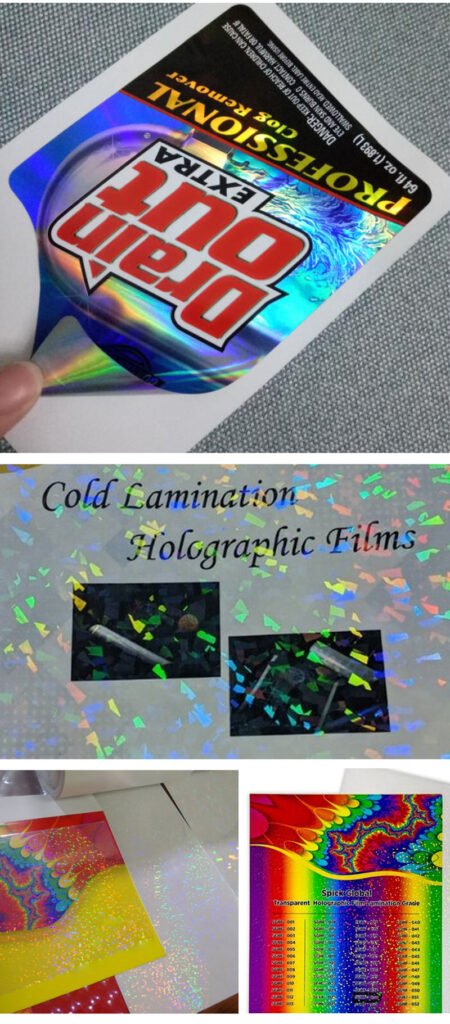

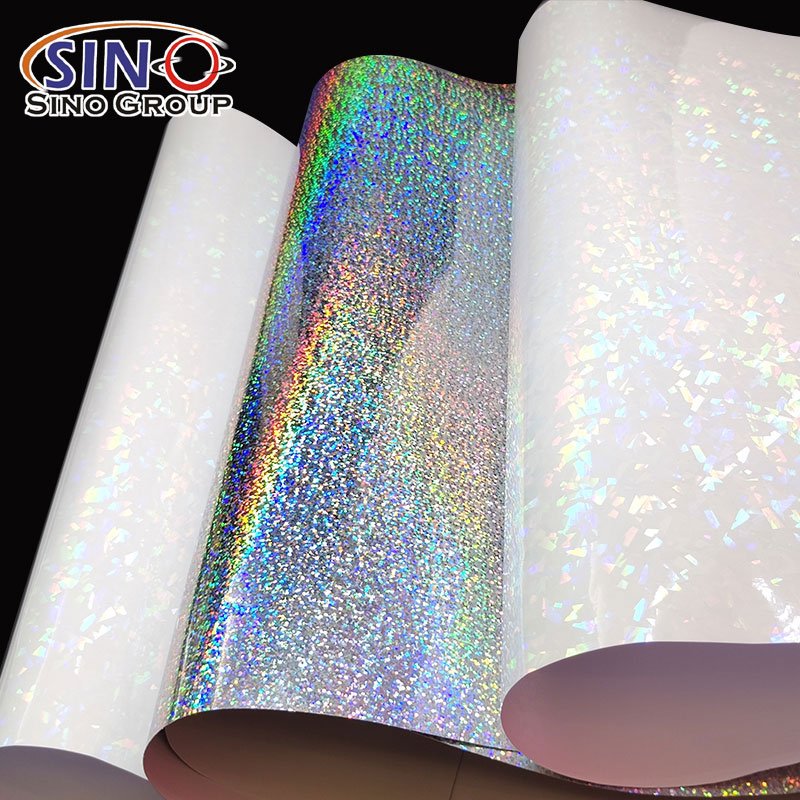

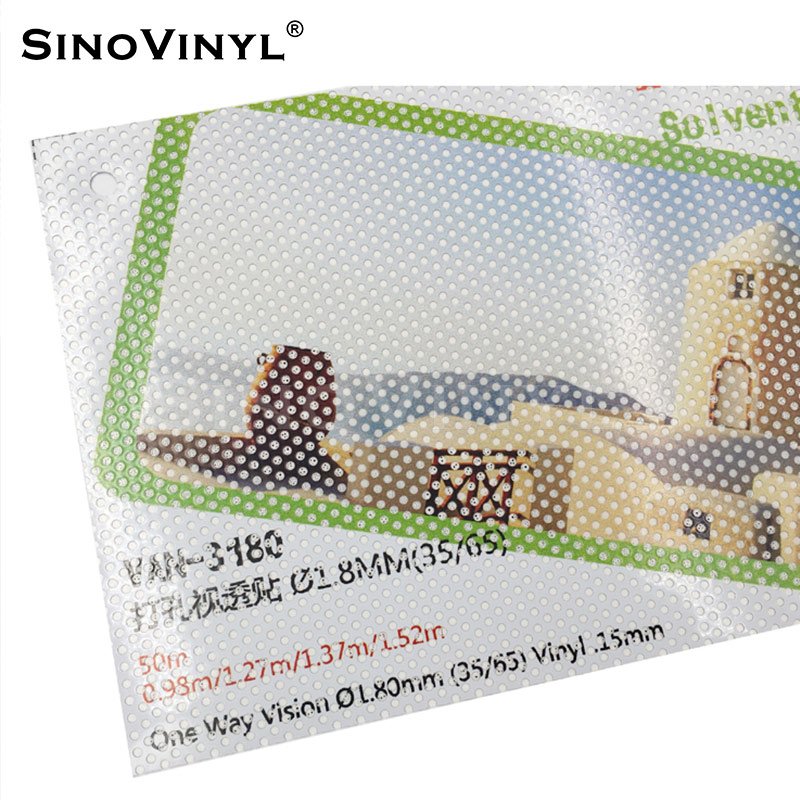

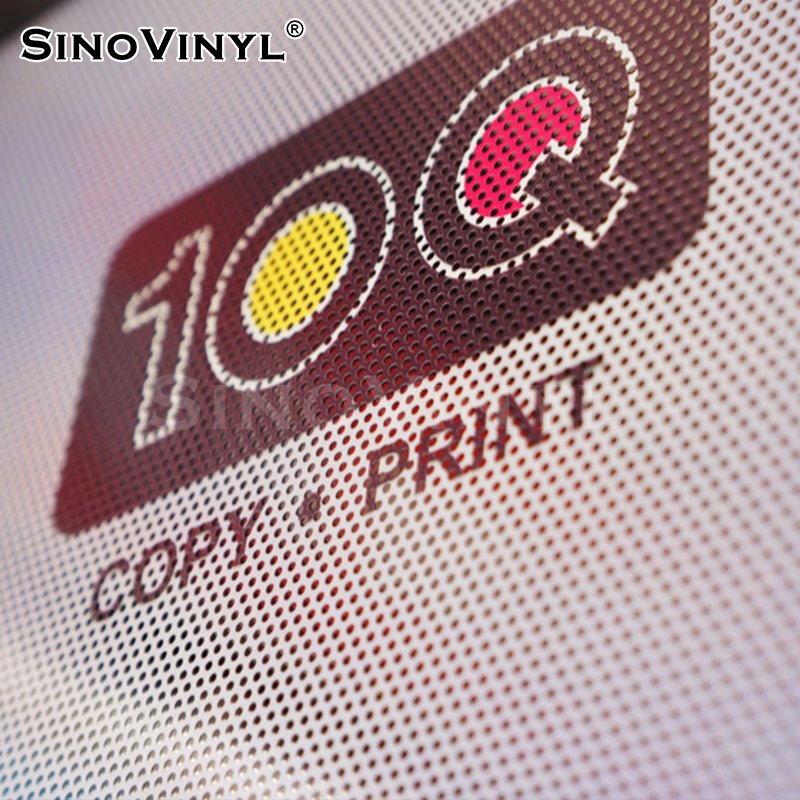

Personalizing home décor with self-adhesive vinyl craft sticker rolls is a fantastic way to add a unique touch and express your creativity throughout your living space. These versatile sticker rolls provide endless possibilities for transforming ordinary items into personalized and visually appealing pieces.

One popular application of self-adhesive vinyl craft sticker rolls is wall decals. With a wide range of colors, patterns, and designs available, you can easily create customized wall art, quotes, or intricate patterns to suit your style and taste. Whether you want to add a whimsical touch to a nursery, create a focal point in your living room, or bring inspiration to your home office, self-adhesive vinyl craft sticker rolls offer a convenient and temporary solution that won’t damage your walls.

Additionally, self-adhesive vinyl craft sticker rolls can be used to personalize furniture. Whether you have a plain coffee table, a lackluster dresser, or a simple bookshelf, these sticker rolls can help you give them a fresh and stylish makeover. You can create unique patterns, designs, or even mimic the appearance of popular materials like marble or wood grain. The self-adhesive nature of the vinyl makes it easy to apply and remove, allowing you to change your design whenever you desire.

Customizing Accessories: How to Upgrade Items with Self-Adhesive Vinyl Craft Sticker Rolls

Here’s a guide on how to upgrade items with self-adhesive vinyl craft sticker rolls or customize accessories:

1. Choose the Right Item or Accessory

Select an item or accessory that you want to upgrade or customize. It could be a phone case, laptop cover, water bottle, tote bag, or any other suitable surface.

2. Clean and Prep the Surface

Ensure that the surface of the item is clean and free from any dust, dirt, or oils. Use a mild soap and water solution or rubbing alcohol to wipe down the surface and let it dry completely.

3. Select the Vinyl Sticker Rolls

Choose self-adhesive vinyl sticker rolls that match your desired design or pattern. Consider the color, style, and size of the stickers according to the item or accessory you are customizing.

4. Plan Your Design

Before applying the stickers, plan out the design you want to create. You can sketch it out on paper or use digital design tools to visualize the placement and arrangement of the stickers.

5. Measure and Cut

Measure the dimensions of the surface area you want to cover with the vinyl stickers. Use a ruler or measuring tape to ensure precise cutting of the sticker rolls to fit the desired area.

6. Peel and Stick

Carefully peel off the backing of the self-adhesive vinyl sticker rolls, starting from one corner. Align the sticker with the desired location on the item or accessory, and gradually apply it, smoothing out any air bubbles or wrinkles as you go.

7. Trim Excess Vinyl

If necessary, trim any excess vinyl sticker material using a craft knife or scissors to achieve a clean and polished look.

8. Heat and Seal (Optional)

If you want to increase the longevity and durability of the stickers, consider using a heat source like a heat gun or hairdryer on a low setting to warm up the vinyl. Gently apply heat to the surface, which will help the adhesive bond more securely.

9. Finishing Touches

Once the stickers are applied and sealed (if applicable), inspect the item or accessory for any loose edges or imperfections. Use a small amount of clear adhesive or sealant, if needed, to secure any loose edges or protect the stickers from wear and tear.

10. Enjoy and Showcase

Allow the adhesive to set and cure according to the manufacturer’s instructions. Once fully dried, your upgraded item or customized accessory is ready to be showcased and enjoyed!

Remember to always follow the manufacturer’s guidelines for the specific vinyl sticker rolls you are using and experiment with different designs and combinations to personalize your items or accessories to your liking.

Step-by-Step Tutorial: Decorating a Journal Cover with Self-Adhesive Vinyl Craft Sticker Rolls

Here’s a step-by-step tutorial on decorating a journal cover with self-adhesive vinyl craft sticker rolls:

Materials Needed

- Journal with a smooth cover

- Self-adhesive vinyl craft sticker rolls in various colors and designs

- Scissors

- Pencil

- Craft knife or precision cutter (optional)

- Ruler (optional)

Step 1: Prepare Your Workspace

Find a clean and well-lit area to work on your journal cover. Make sure the surface is smooth and free from any dust or debris that may interfere with the adhesion of the vinyl stickers.

Step 2: Plan Your Design

Take a moment to visualize your desired design. You can sketch it on a piece of paper or lightly outline it directly on the journal cover using a pencil. This will serve as a guide when applying the vinyl stickers.

Step 3: Cut Out the Vinyl Stickers

Using scissors or a craft knife, carefully cut out the desired shapes and designs from the self-adhesive vinyl craft sticker rolls. You can create various shapes, letters, or decorative elements that align with your planned design.

Step 4: Peel and Stick

Start by peeling the backing off one vinyl sticker. Align it with your design and carefully press it onto the journal cover, starting from one edge and working your way towards the other. Smooth out any air bubbles or wrinkles using your fingers or a small tool, ensuring the sticker adheres firmly to the cover.

Step 5: Layer and Combine

Continue peeling and sticking the vinyl stickers, layering them as desired to create depth and visual interest. Experiment with different colors and designs to achieve the desired effect. Don’t be afraid to overlap stickers or mix and match patterns.

Step 6: Trim Excess Vinyl (Optional)

If necessary, use scissors or a craft knife to trim any excess vinyl that extends beyond the edges of the journal cover. This step will give your design a clean and finished look.

Step 7: Finishing Touches

Once you’re satisfied with the placement and arrangement of the vinyl stickers, take a final look at your design. Make any adjustments if needed. Use a clean cloth or your fingers to gently press down on the stickers, ensuring they are securely attached to the journal cover.

Step 8: Enjoy Your Customized Journal!

Allow the stickers to set for a few minutes before handling or using your journal. Now you have a beautifully decorated journal cover that reflects your personal style and creativity.

Note: Depending on the type of self-adhesive vinyl craft sticker rolls you’re using, the removal process may vary. Some stickers may be repositionable, while others may adhere permanently. Always refer to the manufacturer’s instructions for best practices and tips on using their specific product.

Remember, this tutorial is a basic guideline, and you can adapt and modify the steps to suit your preferences and creativity. Have fun decorating your journal cover with self-adhesive vinyl craft sticker rolls!

Final Words

In conclusion, self-adhesive vinyl craft sticker rolls are a fantastic tool for unleashing your creativity and adding a personalized touch to your craft projects. With the tips and ideas shared in this blog post, you now have a wealth of inspiration to explore. Whether you’re embellishing journals, transforming home decor, or creating unique gifts, the versatility of self-adhesive vinyl craft sticker rolls knows no bounds. Remember to experiment, combine colors and designs, and let your imagination run wild. The possibilities are endless, and the results are sure to impress. So go ahead, get crafty, and let self-adhesive vinyl craft sticker rolls be your artistic companion on this creative journey!