What Is Self-adhesive Vinyl Used For?

Self-adhesive vinyl, also known as adhesive-backed vinyl or simply vinyl, is a versatile material with a sticky backing that allows it to adhere to various surfaces when pressure is applied. It finds wide applications in both residential and commercial settings due to its ease of use, durability, and ability to transform surfaces with minimal effort. Here are some common uses of adhesive vinyl:

1. Home Décor

Self-adhesive vinyl is widely used for home decoration projects. It can be applied to walls, furniture, mirrors, and other smooth surfaces to add patterns, colors, or textures. It’s an excellent option for creating accent walls, faux finishes, and personalized decor elements.

2. DIY Crafts

Crafters and DIY enthusiasts use adhesive vinyl for a wide range of projects. It’s perfect for making stickers, labels, personalized gifts, scrapbooking, card-making, and customizing various items.

3. Signage and Graphics

Self-adhesive vinyl is a popular choice for creating signs, banners, and graphics for businesses, events, and promotions. It can be used both indoors and outdoors, as it is weather-resistant and durable.

4. Vehicle Wraps

Vinyl wraps have become a preferred choice for transforming the appearance of vehicles. Adhesive vinyl is used to wrap car exteriors, giving them a new color, design, or advertisement without the need for expensive paint jobs.

5. Window Graphics

Self-adhesive vinyl can be applied to windows and glass surfaces to create attractive graphics, advertisements, or privacy films.

6. Packaging and Labels

Many products come with adhesive vinyl labels, which are easy to apply to various packaging materials. They can be printed with product information, branding, and barcodes.

7. Interior Design

Interior designers use adhesive vinyl to enhance spaces. It can be applied to doors, cabinets, and even floors to give them a fresh look or to mimic the appearance of more expensive materials like wood or marble.

8. Schools and Educational Settings

Teachers and educators often use self-adhesive vinyl for educational purposes, such as creating learning aids, visual aids, and classroom displays.

9. Temporary Decorations

Self-adhesive vinyl is ideal for temporary decorations, such as seasonal decorations during holidays or special events.

10. Commercial Branding

Businesses often use adhesive vinyl for branding purposes. It can be applied to storefront windows, walls, and other surfaces to showcase the company logo, promotions, or contact information.

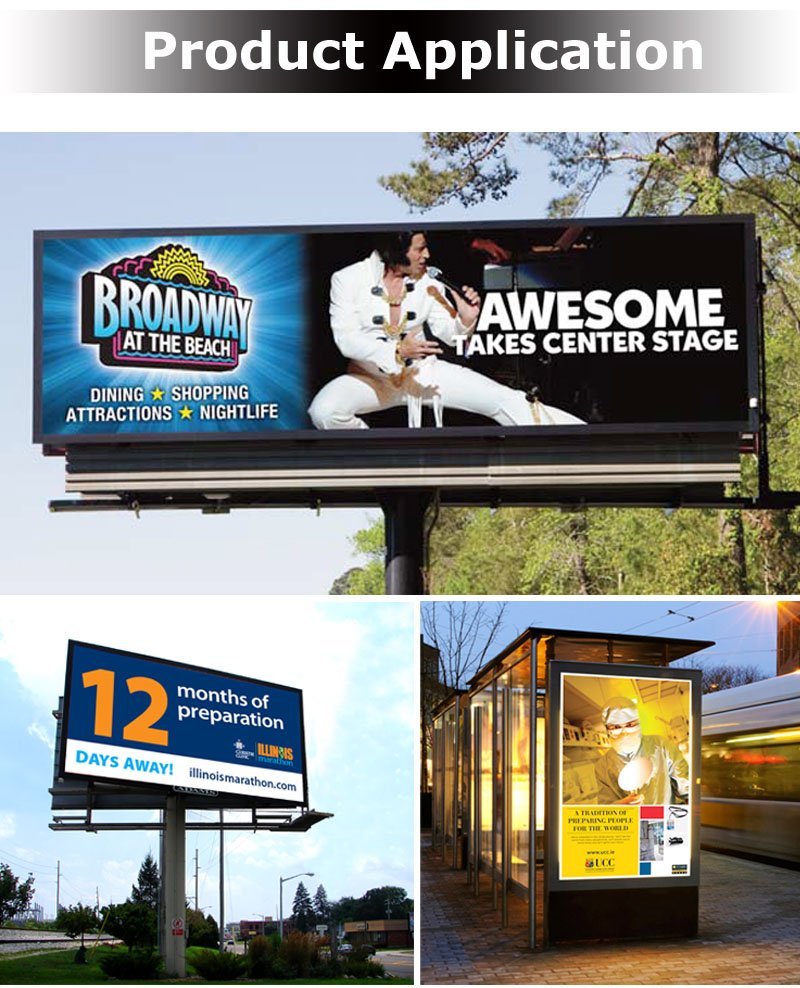

11. Advertising and Marketing

Self-adhesive vinyl is widely used in advertising and marketing campaigns. It can be applied to billboards, buses, subway stations, and other surfaces to grab attention and promote products or services.

The uses of adhesive vinyl are vast, and its versatility makes it a popular choice for numerous applications in various industries. Its easy application, durability, and cost-effectiveness have contributed to its widespread adoption in both personal and professional projects.

10 Creative DIY Projects Using Self-Adhesive Vinyl

Here are 10 creative DIY projects using self-adhesive vinyl:

1. Custom Laptop Skin

Personalize your laptop by creating a unique and stylish vinyl skin with your favorite patterns or designs.

2. Decorative Mason Jars

Transform plain mason jars into charming vases or storage containers by wrapping them with self-adhesive vinyl in various colors and patterns.

3. DIY Wall Art

Cut out intricate shapes or inspiring quotes from self-adhesive vinyl to create stunning wall art that adds a touch of elegance to any room.

4. Kitchen Appliance Makeover

Give your kitchen a facelift by applying self-adhesive vinyl to your appliances, turning them from basic to eye-catching focal points.

5. Custom Water Bottles

Make personalized water bottles by decorating them with self-adhesive vinyl stickers featuring your name, favorite quotes, or designs.

6. Upcycled Furniture

Breathe new life into old furniture pieces by adding self-adhesive vinyl to surfaces, creating a fresh and modern look.

7. DIY Laptop or Tablet Stand

Craft a custom laptop or tablet stand using self-adhesive vinyl and a sturdy base, making it a functional and visually appealing addition to your workspace.

8. Patterned Plant Pots

Jazz up plain plant pots with self-adhesive vinyl in vibrant colors and patterns, adding flair to your indoor or outdoor greenery.

9. Kids’ Room Decals

Create fun and interactive decals for your kids’ room using self-adhesive vinyl, such as cute animals, stars, or alphabet letters.

10. DIY Gift Labels and Tags

Design and cut your own gift labels and tags with self-adhesive vinyl, making your presents even more special and personalized.

These DIY projects showcase the versatility of self-adhesive vinyl and offer endless opportunities for creativity and customization. Enjoy experimenting with different designs and ideas!

Tips for Applying Self-Adhesive Vinyl with Precision

Applying self-adhesive vinyl with precision is crucial to achieving a clean and professional-looking result. Here are some tips to help you get it right:

1. Clean and Prepare the Surface

Before applying the vinyl, ensure that the surface is clean, smooth, and free from dust, dirt, or any other debris. Use a mild cleaner and a lint-free cloth to wipe the surface thoroughly.

2. Measure and Mark

Take accurate measurements of the area where you want to apply the vinyl. Use a pencil or painter’s tape to mark the boundaries of the vinyl placement. This step will help you position the vinyl correctly.

3. Use a Level or T-Square

For straight alignments, use a level or T-square to ensure the vinyl is applied in a straight line. It will prevent the vinyl from appearing crooked or uneven.

4. Create a Hinge

To apply larger pieces of vinyl, create a “hinge” using painter’s tape. Apply a strip of tape along the top edge of the vinyl, leaving a portion of the backing exposed. This allows you to position the vinyl accurately before fully adhering it.

5. Work Slowly and Smoothly

Peel back a small section of the backing and start applying the vinyl from one end to the other. Use your hand or a squeegee to smooth the vinyl as you go. Working slowly and steadily will minimize air bubbles and wrinkles.

6. Use a Squeegee

A squeegee is a valuable tool for applying vinyl with precision. It helps to eliminate air bubbles and ensures even adhesion. Start from the center of the vinyl and work your way out towards the edges.

7. Lift and Reapply if Necessary

If you notice any misalignment or imperfections while applying the vinyl, gently lift the vinyl and reposition it. The self-adhesive nature of the vinyl allows for reapplication, but be careful not to stretch or distort the material.

8. Heating and Stretching

In some cases, you may need to apply heat to the vinyl to help it conform to curved or irregular surfaces. A heat gun or hairdryer can be used for this purpose. Be cautious not to overheat the vinyl, as it may cause damage.

9. Trim Excess Vinyl

Once the vinyl is applied, use a sharp utility knife or a cutting tool to trim any excess material carefully. Pay attention to corners and edges for a clean finish.

10. Seal the Edges

If you want to add extra protection or prevent the edges from peeling, consider using a vinyl sealer or clear coat over the applied vinyl.

Remember, practice makes perfect. If you’re new to working with self-adhesive vinyl, consider starting with small projects to gain confidence before tackling larger and more intricate designs.

Final Words

In conclusion, self-adhesive vinyl is an absolute game-changer when it comes to elevating your DIY projects and unleashing your creativity. With its remarkable versatility and ease of use, this material opens up a world of possibilities for transforming spaces, customizing décor, and crafting personalized gifts with precision and style. Whether you’re a seasoned DIY enthusiast or just starting your creative journey, self-adhesive vinyl offers a user-friendly and cost-effective solution to revamp your home, add a touch of professionalism to your business, or create unique and eye-catching designs.