Different Types of Printed Self Adhesive Vinyl Film Roll Available

1. Matte Finish Printed Self Adhesive Vinyl Film Roll

This type of vinyl film roll offers a non-reflective, smooth surface, providing a subtle and sophisticated look.

2. Glossy Finish Printed Self Adhesive Vinyl Film Roll

If you’re looking for a vibrant and shiny appearance, the glossy finish vinyl film roll is a popular choice. It adds a sleek and polished effect to surfaces.

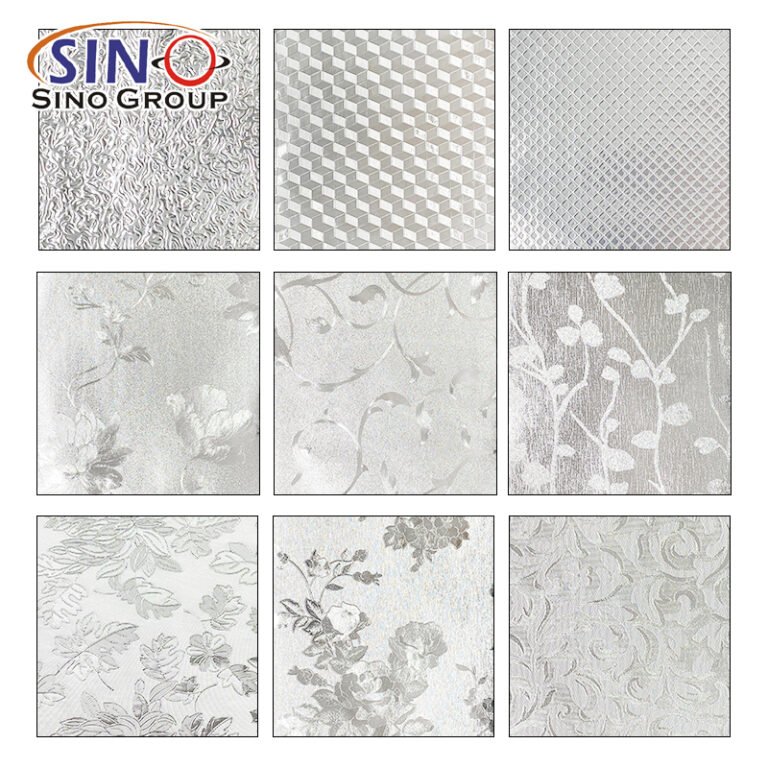

3. Textured Printed Self Adhesive Vinyl Film Roll

Textured vinyl film rolls come in various patterns and textures, such as wood grain, stone, or fabric. They add depth and a realistic feel to surfaces, mimicking the look of different materials.

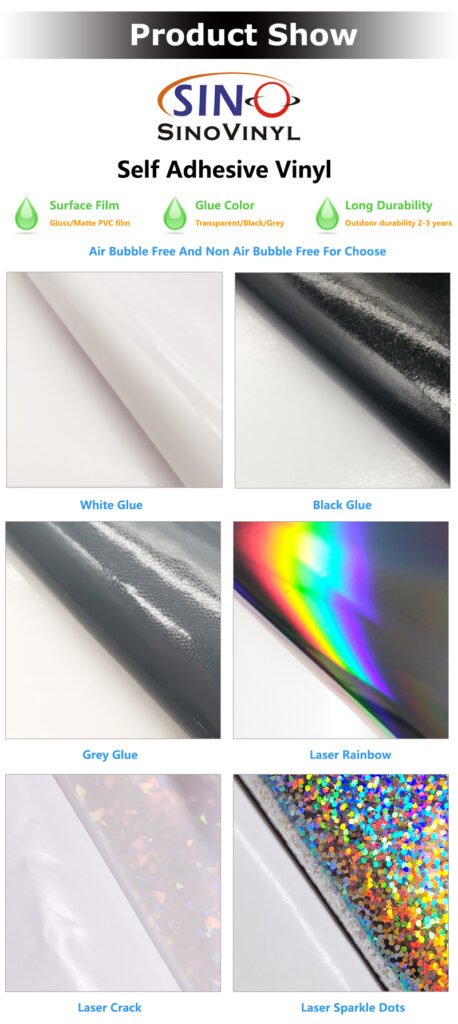

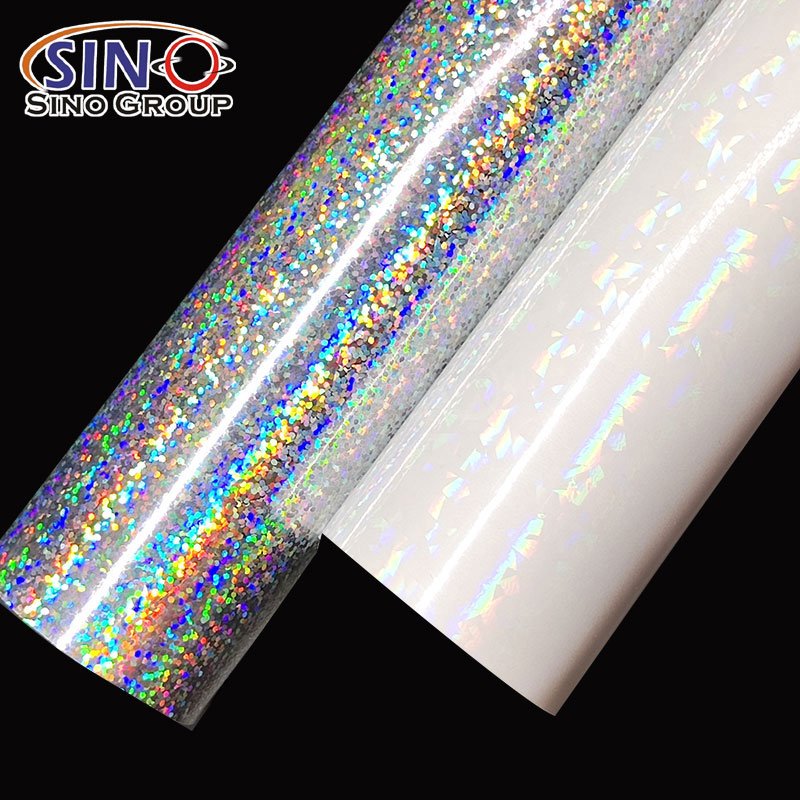

4. Metallic Printed Self Adhesive Vinyl Film Roll

Metallic vinyl film rolls are designed to give a metallic or chrome-like effect, making surfaces stand out with a modern and reflective appearance.

5. Frosted Printed Self Adhesive Vinyl Film Roll

Frosted vinyl film rolls are perfect for adding privacy and diffusing light while maintaining an elegant and translucent look. They are commonly used on windows, glass doors, and partitions.

6. Patterned Printed Self Adhesive Vinyl Film Roll

Patterned vinyl film rolls feature a wide range of designs and motifs, such as floral, geometric, or abstract patterns. They are ideal for adding a decorative touch to surfaces.

7. Chalkboard Printed Self Adhesive Vinyl Film Roll

Chalkboard vinyl film rolls provide a surface that can be written on with chalk, allowing for creativity and communication in various settings, such as offices, kitchens, or classrooms.

8. Dry Erase Printed Self Adhesive Vinyl Film Roll

Similar to chalkboard film rolls, dry erase vinyl film rolls offer a writable surface using dry erase markers. They are commonly used in offices, conference rooms, and educational environments.

9. Clear Printed Self Adhesive Vinyl Film Roll

Clear vinyl film rolls are transparent and provide a protective layer while maintaining the original appearance of the surface. They are often used for preserving and safeguarding printed materials or graphics.

10. UV-Resistant Printed Self Adhesive Vinyl Film Roll

UV-resistant vinyl film rolls are specifically designed to withstand the effects of sunlight exposure, preventing fading and ensuring long-lasting color vibrancy, making them suitable for outdoor applications.

These are just a few examples of the different types of printed self adhesive vinyl film rolls available. Each type offers unique characteristics and benefits, catering to various design preferences and functional requirements.

Exploring Creative Design Ideas with Printed Self Adhesive Vinyl Film Roll

1. Nature-inspired Murals

Create a stunning nature-themed mural on your wall using printed self adhesive vinyl film roll. Choose designs like lush forests, serene beaches, or blooming flowers to bring the outdoors inside.

2. Geometric Patterns

Experiment with bold geometric patterns to add a modern and artistic touch to your space. Play with shapes, colors, and sizes to create a visually striking design.

3. Faux Brick or Stone Accent Wall

Give your room an industrial or rustic look by applying printed self adhesive vinyl film roll that mimics the appearance of exposed brick or natural stone. It’s a great way to add texture and character to any space.

4. Inspirational Quotes or Typography

Use printed self adhesive vinyl film roll to display your favorite quotes, motivational messages, or meaningful words. Apply them to walls, doors, or even furniture to add a personalized and uplifting touch.

5. Colorful Backsplash

Transform your kitchen or bathroom with a vibrant and eye-catching backsplash. Choose a printed self adhesive vinyl film roll with bold colors or patterns to instantly revitalize the space.

6. Customized Decals

Create unique and personalized decals using printed self adhesive vinyl film roll. From family monograms to custom graphics, decals can be applied to walls, windows, laptops, or any other smooth surface.

7. Children’s Room Themes

Bring your child’s favorite characters, animals, or storybook scenes to life using printed self adhesive vinyl film roll. It’s an excellent way to add a playful and imaginative element to their room.

8. Trompe-l’oeil Effects

Use printed self adhesive vinyl film roll to create optical illusions like faux windows, open doorways, or even a bookshelf filled with books. These creative tricks can add depth and intrigue to your space.

9. Vintage Patterns

Give your room a retro or vintage vibe by using printed self adhesive vinyl film roll with nostalgic patterns, such as mid-century modern designs, vintage floral motifs, or old-fashioned tile patterns.

10. Seasonal Themes

Change the look and feel of your space with the seasons. Opt for printed self adhesive vinyl film roll with seasonal motifs like falling leaves for autumn, snowflakes for winter, or blooming flowers for spring.

Remember, the possibilities are endless when it comes to designing with printed self adhesive vinyl film roll. Let your imagination run wild and create a space that reflects your personal style and taste.

How to Properly Prepare Surfaces for Applying Printed Self Adhesive Vinyl Film Roll

Properly preparing the surfaces before applying printed self-adhesive vinyl film roll is crucial for achieving a successful and long-lasting installation. Here is a step-by-step guide on how to prepare surfaces effectively:

1. Clean the surface

Start by thoroughly cleaning the surface where you plan to apply the vinyl film. Remove any dust, dirt, grease, or other residues using a mild detergent or a surface cleaner. Wipe down the surface with a clean cloth to ensure it is completely clean and dry.

2. Smooth out imperfections

Inspect the surface for any bumps, cracks, or imperfections. Fill in any holes or cracks with a suitable filler and use a putty knife to smooth out the surface. Allow the filler to dry completely before proceeding.

3. Sand rough surfaces

If the surface is rough or uneven, lightly sand it with fine-grit sandpaper. This step helps create a smoother surface for better adhesion of the vinyl film. After sanding, make sure to remove any dust or debris.

4. Ensure proper adhesion

The surface should be free from any loose paint or varnish. If there are any peeling or flaking areas, scrape off the loose paint using a scraper or sandpaper. For glossy or painted surfaces, consider using a deglosser or a liquid sandpaper product to create a slightly rough texture that promotes adhesion.

5. Test for compatibility

Before applying the vinyl film to the entire surface, it’s a good idea to perform a small test patch in an inconspicuous area. This test will help ensure that the adhesive backing of the vinyl film adheres well to the surface without any adverse reactions.

6. Allow proper curing time

If you have freshly painted the surface, make sure to follow the manufacturer’s recommendations for curing time. It is important to wait until the paint is fully cured before applying the vinyl film to avoid any damage or adhesion issues.

By following these preparation steps, you can create an optimal surface for the application of printed self-adhesive vinyl film roll. Remember to carefully read and follow the manufacturer’s instructions specific to the product you are using for the best results.

Durability and Longevity of Printed Self Adhesive Vinyl Film Roll: What to Expect

Printed self adhesive vinyl film roll offers a durable and long-lasting solution for surface enhancement. Here’s what you can expect in terms of durability and longevity:

1. Durability

Printed self adhesive vinyl film roll is designed to withstand daily wear and tear. It is made from high-quality vinyl materials that are resistant to scratches, fading, and water damage. This makes it suitable for both indoor and outdoor applications.

2. UV Resistance

One of the key features of printed self adhesive vinyl film roll is its ability to resist UV rays. This means that the vibrant colors and designs printed on the film will remain vivid and vibrant even when exposed to direct sunlight for extended periods. UV resistance helps prevent fading and ensures long-lasting visual appeal.

3. Moisture Resistance

Printed self adhesive vinyl film roll is also resistant to moisture, making it suitable for use in areas prone to humidity, such as kitchens and bathrooms. It can withstand occasional splashes of water and is easy to clean with mild soap and water, ensuring its longevity even in moisture-prone environments.

4. Longevity

The lifespan of printed self adhesive vinyl film roll can vary depending on various factors such as the quality of the film, installation technique, and maintenance. However, under normal conditions and proper care, it can last anywhere from 5 to 10 years or even longer.

5. Easy Replacement

In case of any damage or if you wish to update the design, printed self adhesive vinyl film roll can be easily removed and replaced without causing damage to the underlying surface. This flexibility allows you to refresh your space without the need for extensive renovations.

It’s important to note that the durability and longevity of printed self adhesive vinyl film roll can be influenced by factors such as the quality of the product, surface preparation, installation technique, and maintenance. Following the manufacturer’s instructions and best practices will help maximize its durability and ensure long-lasting results.

Final Words

In conclusion, printed self adhesive vinyl film roll is a versatile and transformative solution that can unlock the potential of your surfaces. With its durability, UV resistance, and moisture resistance, it offers a long-lasting and visually appealing enhancement to any space. Whether you’re looking to revamp your home decor, create a professional atmosphere in your office, or showcase your brand in a retail setting, printed self adhesive vinyl film roll provides endless design possibilities. Its easy installation and removal make it a convenient choice for DIY enthusiasts and professionals alike. So go ahead and explore the world of printed self adhesive vinyl film roll, and unleash your creativity to transform your surfaces into stunning showcases of style and personality.