Exploring the Different Types of Ejet Self Adhesive Vinyl

When it comes to Ejet self-adhesive vinyl, there are several different types available, each catering to specific needs and applications. Here are some of the common types of Ejet self-adhesive vinyl:

1. Matte Vinyl: Matte vinyl offers a non-reflective surface, giving your designs a smooth and sophisticated look. It is ideal for indoor applications such as wall graphics, decals, and signage.

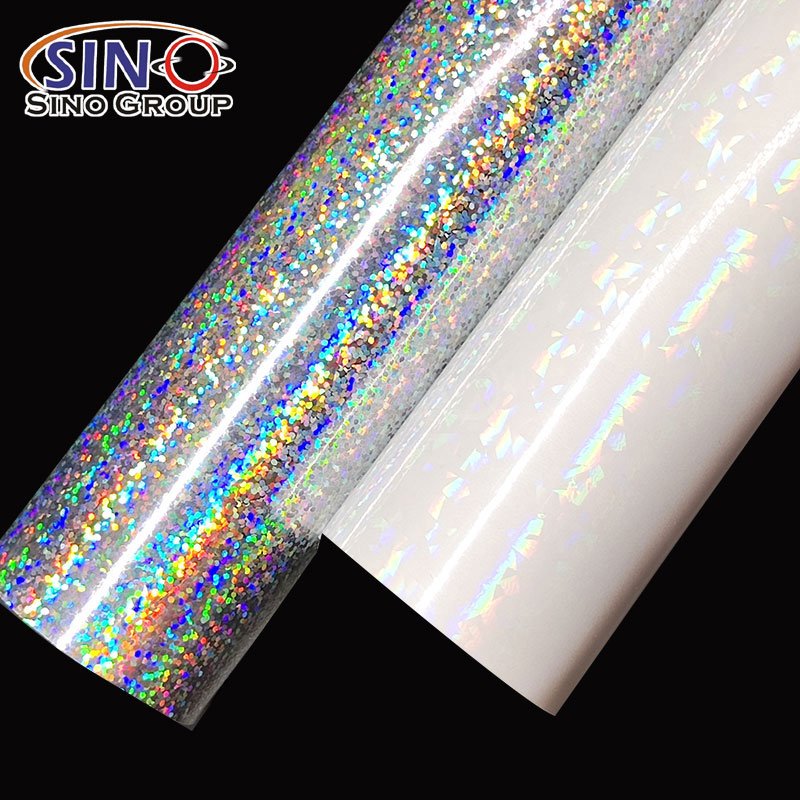

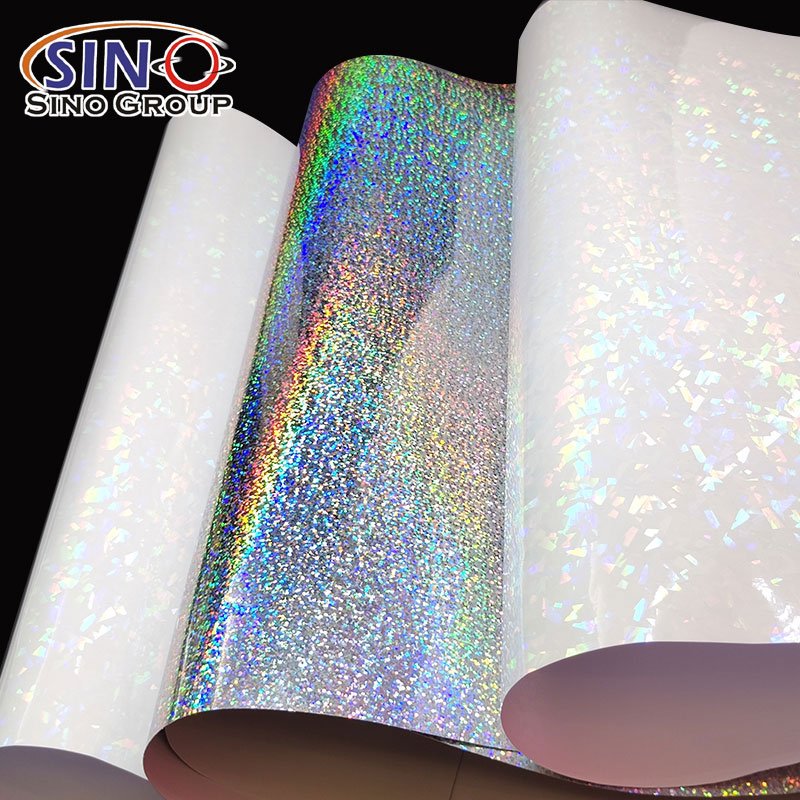

2. Glossy Vinyl: Glossy vinyl provides a shiny, reflective finish that enhances colors and creates a vibrant appearance. It is commonly used for outdoor applications like window graphics, vehicle wraps, and promotional displays.

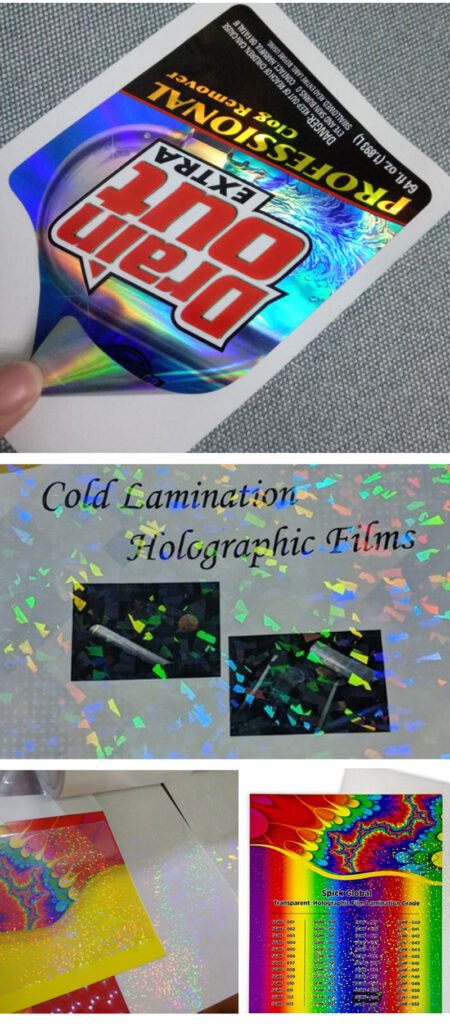

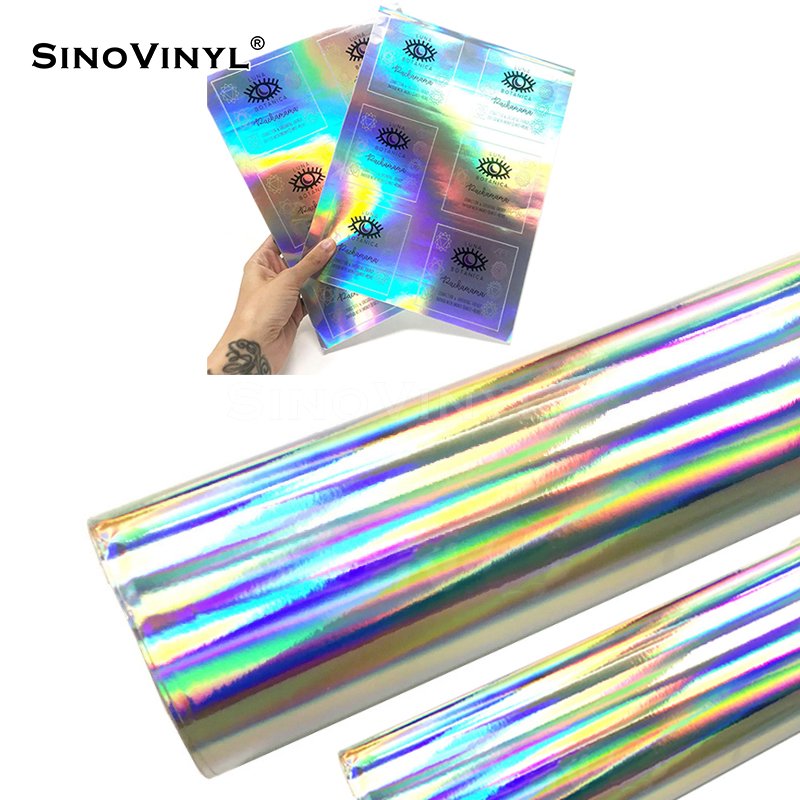

3. Transparent Vinyl: Transparent vinyl, also known as clear vinyl, allows you to create designs that seamlessly blend with the surface they are applied to. It is perfect for creating the illusion of floating graphics, glass decals, or showcasing the underlying surface.

4. Textured Vinyl: Textured vinyl adds a tactile element to your designs, providing a unique visual and sensory experience. It comes in various finishes like canvas, leather, wood grain, and more, offering versatility for interior design projects and creative applications.

5. Removable Vinyl: Removable vinyl is designed to be easily peeled off without leaving residue or damaging the surface. It is ideal for temporary applications, such as seasonal decorations, event signage, or wall decals that can be changed or removed as needed.

6. Permanent Vinyl: Permanent vinyl is intended for long-term applications, providing a strong adhesive bond to ensure durability and resistance to weather conditions. It is commonly used for outdoor signs, vehicle graphics, and other projects that require a lasting finish.

7. Heat Transfer Vinyl (HTV): HTV, also known as iron-on vinyl, is specifically designed for creating customized designs on fabrics. It can be applied using heat and pressure, making it popular for creating personalized apparel, tote bags, and other fabric-based crafts.

These are just a few examples of the different types of Ejet self-adhesive vinyl available in the market. The choice of vinyl type depends on your specific project requirements, desired finish, and intended application surface.

Unleashing Your Creativity: Artistic Possibilities with Ejet Self Adhesive Vinyl

Artistic possibilities abound when it comes to exploring the versatile nature of Ejet self-adhesive vinyl. This remarkable material opens up a world of creative opportunities for artists, crafters, and DIY enthusiasts alike. With its wide range of colors, finishes, and textures, Ejet self-adhesive vinyl serves as a blank canvas for expressing artistic visions in unique and captivating ways.

One of the key advantages of Ejet self-adhesive vinyl is its ease of use. Artists can effortlessly cut, shape, and manipulate the vinyl to suit their creative needs. Whether it’s creating intricate designs, bold patterns, or delicate embellishments, this material allows for precise and intricate work. Its adhesive backing ensures a strong bond to various surfaces, allowing artists to explore a multitude of applications.

Transforming Furniture with Ejet Self Adhesive Vinyl: A DIY Project

If you’re looking to give your old furniture a fresh and stylish makeover, look no further than Ejet Self Adhesive Vinyl. This versatile material is not only perfect for walls and floors but can also be used to completely transform your furniture. In this DIY project, we’ll guide you through the step-by-step process of using Ejet Self Adhesive Vinyl to breathe new life into your beloved pieces.

1. Choosing the Right Furniture

Discover which types of furniture work best for this project and select pieces that have a smooth and clean surface for optimal adhesion.

2. Preparing the Furniture

Learn how to properly clean and prep the furniture before applying the Ejet Self Adhesive Vinyl. This step is crucial to ensure a smooth and long-lasting finish.

3. Selecting the Vinyl Design

Explore various patterns, colors, and textures of Ejet Self Adhesive Vinyl to find the perfect match for your furniture and desired aesthetic.

4. Measuring and Cutting

Master the art of accurate measuring and cutting techniques to ensure precise application and minimal waste of the adhesive vinyl.

5. Applying the Vinyl

Follow our detailed instructions on how to apply the Ejet Self Adhesive Vinyl to your furniture, including tips on avoiding air bubbles and achieving a seamless finish.

6. Dealing with Curves and Edges

Learn techniques for handling curves, corners, and edges of your furniture to achieve a professional-looking result.

7. Adding Extra Details

Discover creative ways to enhance your furniture makeover by incorporating additional elements like trims, handles, or decorative accents.

8. Finishing Touches

Find out how to properly seal and protect the Ejet Self Adhesive Vinyl to ensure its longevity and resistance to everyday wear and tear.

9. Showcasing Your Transformed Furniture

Learn how to style and incorporate your newly transformed furniture into your living space for maximum impact.

10. Troubleshooting and Maintenance

Gain insights into common challenges and how to overcome them, as well as tips for cleaning and maintaining your Ejet Self Adhesive Vinyl furniture.

By the end of this DIY project, you’ll have the skills and knowledge to confidently revamp your furniture using Ejet Self Adhesive Vinyl. Get ready to unleash your creativity and enjoy the satisfaction of transforming your space with this versatile material.

Incorporating Ejet Self Adhesive Vinyl in Your Business Signage

Incorporating Ejet Self Adhesive Vinyl in your business signage is a creative and cost-effective way to enhance your brand visibility and make a lasting impression on customers. Here’s a step-by-step guide on how to do it:

1. Determine your signage needs

Start by assessing the type of signage you require for your business. This could include window decals, wall graphics, banners, or even vehicle wraps. Identify the areas where you want to incorporate Ejet Self Adhesive Vinyl.

2. Select the appropriate vinyl type

Ejet Self Adhesive Vinyl comes in various types and finishes, such as matte, glossy, or textured. Consider the location, durability requirements, and visual appeal when choosing the right vinyl for your signage.

3. Design your signage

Create a visually appealing design that aligns with your brand identity. You can hire a graphic designer or use design software to develop custom artwork or incorporate your logo, tagline, and other relevant elements. Ensure that your design is compatible with the dimensions and specifications of your signage.

4. Prepare the surface

Clean and prepare the surface where you will be applying the vinyl. Ensure it is smooth, dry, and free from any dust, grease, or debris. This step is crucial for proper adhesion and longevity of the vinyl.

5. Measure and cut the vinyl

Take accurate measurements of the signage area and cut the Ejet Self Adhesive Vinyl accordingly. Leave some extra material around the edges for adjustments during installation.

6. Apply the vinyl

Peel off the backing of the vinyl carefully and align it with the desired position on the signage surface. Start from one corner and gradually smooth out the vinyl using a squeegee or a credit card, working out any air bubbles or wrinkles as you go along. Pay attention to details and ensure a smooth and even application.

7. Trim and finish

Once the vinyl is applied, trim any excess material using a sharp blade or scissors. Take your time to achieve clean and precise cuts. Pay attention to corners and edges to ensure a professional finish.

8. Final touches

Step back and review your signage for any imperfections or uneven areas. Make any necessary adjustments or touch-ups to ensure a polished and professional look.

9. Maintenance and care

Follow the manufacturer’s instructions for maintenance and care of the Ejet Self Adhesive Vinyl. Regularly clean the signage to keep it looking vibrant and extend its lifespan.

By incorporating Ejet Self Adhesive Vinyl in your business signage, you can create eye-catching displays that effectively communicate your brand message and attract customers.

Ejet Self Adhesive Vinyl for Window Decals: Enhancing Privacy and Aesthetics

Applying Ejet Self Adhesive Vinyl to create window decals for enhancing privacy and aesthetics is a relatively simple process. Here’s a step-by-step guide to help you:

Materials needed

- Ejet Self Adhesive Vinyl

- Scissors or utility knife

- Measuring tape or ruler

- Spray bottle filled with water and a few drops of dish soap

- Squeegee or credit card

- Lint-free cloth or paper towels

Step 1: Prepare the Window Surface

Ensure that the window is clean and free from any dust, dirt, or grease. Use a glass cleaner or a mixture of water and vinegar to clean the surface thoroughly. Wipe it dry with a lint-free cloth or paper towels.

Step 2: Measure and Cut the Vinyl

Measure the dimensions of the window you want to cover using a measuring tape or ruler. Add an extra inch or two to each side of the measurement to allow for a margin of error and easier application. Transfer the measurements onto the Ejet Self Adhesive Vinyl and cut it to the desired size using scissors or a utility knife.

Step 3: Prepare the Vinyl

Peel off a small portion of the backing paper from the Ejet Self Adhesive Vinyl, exposing the adhesive side. Spray the adhesive side with the water and dish soap mixture. This will create a slight slipperiness that allows you to position the vinyl correctly.

Step 4: Apply the Vinyl to the Window

Carefully align the exposed portion of the vinyl with one edge of the window. Slowly press the vinyl onto the window, using your hand or a squeegee to smooth it out and remove any air bubbles. Continue peeling off the backing paper and pressing the vinyl onto the window, working from one side to the other until the entire decal is applied.

Step 5: Remove Air Bubbles

Once the vinyl is applied, use a squeegee or credit card to smooth out any remaining air bubbles. Start from the center and push the bubbles towards the edges, ensuring a flat and even application.

Step 6: Trim Excess Vinyl

After successfully applying the vinyl, use scissors or a utility knife to trim any excess material along the edges of the window. Be careful not to cut into the window frame or surrounding surfaces.

Step 7: Finishing Touches

Once the vinyl is applied and trimmed, use a lint-free cloth or paper towels to gently wipe away any excess moisture or cleaning solution from the window. This will help the vinyl adhere better and prevent any smudges or streaks.

That’s it! By following these steps, you can apply Ejet Self Adhesive Vinyl to create beautiful window decals that enhance privacy and aesthetics.

(Click the picture to learn more)

Final Words

In conclusion, Ejet Self Adhesive Vinyl opens up a world of creative possibilities, allowing you to unleash your inner artist and transform any space with ease. Whether you’re looking to revamp your home decor, personalize your belongings, or add a professional touch to your business signage, this versatile material offers endless opportunities for expression. With its easy application process and wide range of colors and finishes, Ejet Self Adhesive Vinyl empowers you to bring your artistic vision to life. So, go ahead and explore the boundless potential of Ejet Self Adhesive Vinyl, and let your imagination soar as you embark on a journey of self-expression and creativity. Unleash your inner artist today and experience the transformative power of Ejet Self Adhesive Vinyl.