Understanding the Eco Solvent Printing Process

Eco solvent printing is a digital printing process that utilizes eco-friendly solvent-based inks to create high-quality and durable prints. This printing method is commonly used for large-format printing applications, such as banners, vehicle wraps, signage, and labels. It offers several advantages over traditional solvent-based printing, making it a popular choice for businesses and individuals looking for a more environmentally friendly printing solution.

The process of eco solvent printing involves the following steps:

1. Designing

The first step is to create or prepare the artwork or design that will be printed. This can be done using graphic design software or by outsourcing the design work to a professional.

2. Preparing the Printer

The eco solvent printer needs to be properly set up and calibrated for optimal print quality. This includes loading the eco solvent ink cartridges, adjusting the print heads, and ensuring the printer is connected to a computer or network for data transfer.

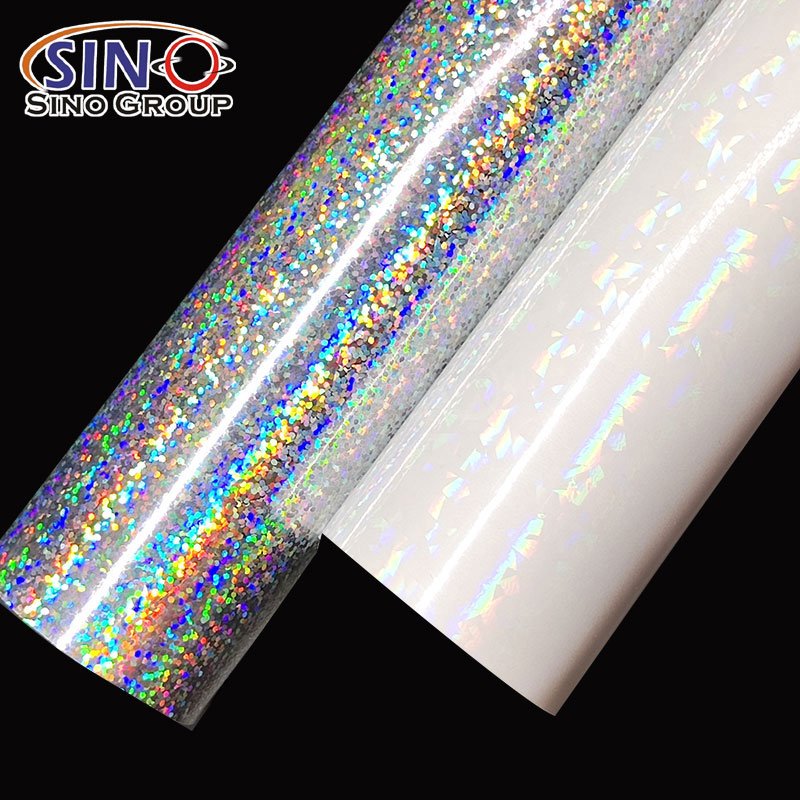

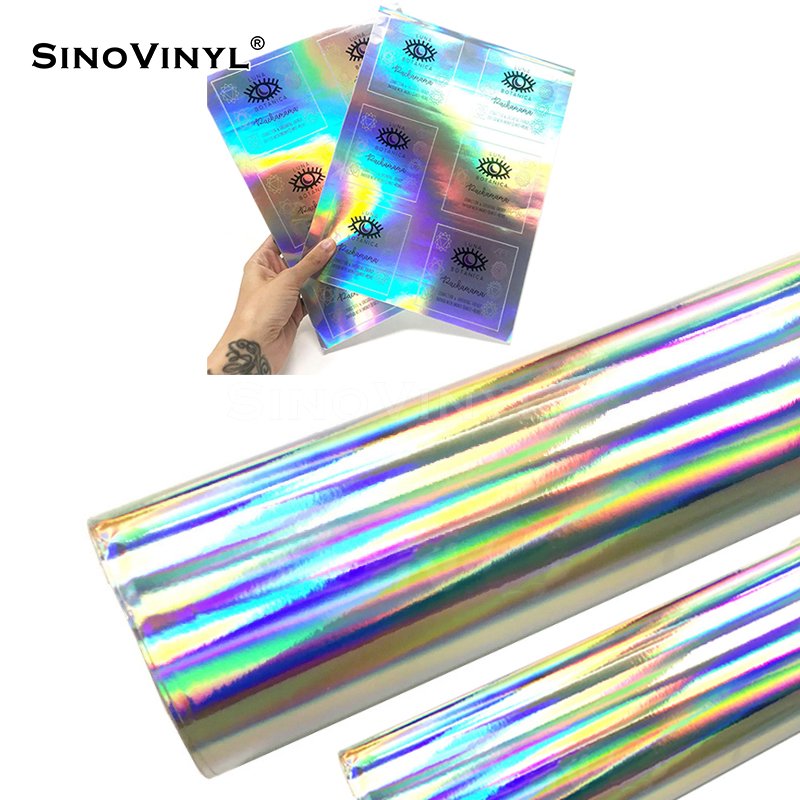

3. Material Selection

Choose the appropriate eco solvent printable self-adhesive vinyl roll based on the specific requirements of your project. Consider factors such as size, thickness, finish, and adhesive properties to ensure compatibility with the printer and desired application.

4. Printing

Once the printer and materials are ready, the design is sent to the printer for printing. The eco solvent ink is sprayed onto the vinyl material using advanced inkjet technology. The ink contains pigments that bond with the vinyl substrate, resulting in vibrant and long-lasting prints.

5. Drying and Curing

After printing, the eco solvent ink needs to dry and cure. This process may involve using heaters or fans to accelerate drying time, depending on the printer and ink manufacturer’s recommendations. Proper drying and curing ensure the ink adheres well to the vinyl and enhances its durability.

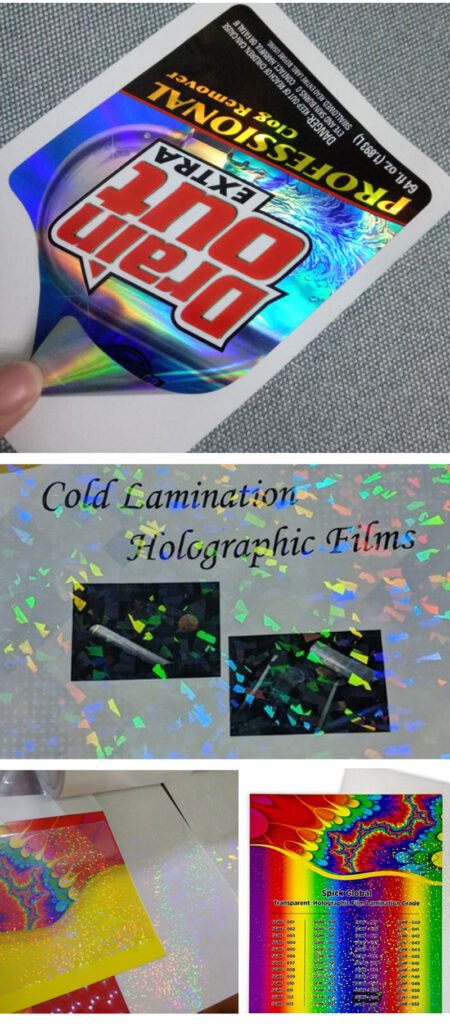

6. Cutting and Finishing

Once the print is dry, it can be cut into the desired shape and size using a cutting plotter or other cutting tools. This step is particularly important for creating precise and custom-shaped prints. Additional finishing techniques, such as lamination or application of protective coatings, may be employed to enhance the print’s longevity and resistance to environmental factors.

7. Application

The final step involves applying the eco solvent printable self-adhesive vinyl roll to the desired surface. This could be a wall, window, vehicle, or any other suitable substrate. Careful and precise application is essential to achieve a smooth and professional-looking finish.

By following these steps, eco solvent printing delivers high-quality prints with excellent color reproduction, durability, and resistance to fading and weathering. Moreover, the eco solvent inks used in this process contain lower levels of volatile organic compounds (VOCs), making them safer for the environment and human health compared to traditional solvent inks.

Tips for Choosing the Right Eco Solvent Printable Self Adhesive Vinyl Roll

Here are some tips for operating the right eco solvent printable self adhesive vinyl roll:

1. Select the appropriate vinyl roll

Ensure that you choose the correct type and size of eco solvent printable self adhesive vinyl roll that suits your printing needs. Consider factors such as the surface you’ll be applying it to, the intended duration of the print, and the desired finish.

2. Prepare the printing environment

Create a clean and dust-free environment for printing to avoid any particles interfering with the adhesive properties of the vinyl. Keep the printing area well-ventilated to dissipate any fumes generated during the printing process.

3. Calibrate your printer

Properly calibrate your printer to ensure accurate color reproduction and optimal print quality. Adjust the settings according to the manufacturer’s recommendations for the specific eco solvent printable self adhesive vinyl roll you’re using.

4. Perform test prints

Before embarking on a large print job, conduct test prints to verify the color accuracy, print resolution, and overall quality. This will help you identify any adjustments needed before printing the final project.

5. Handle the vinyl roll carefully

Avoid bending or folding the vinyl roll, as it can damage the material or create unwanted creases. Store the roll in a cool and dry place to maintain its integrity and prevent any curling.

6. Clean the printing surface

Make sure the surface where you will be applying the vinyl is clean, dry, and free from any debris or dust particles. This will ensure proper adhesion and longevity of the print.

7. Use appropriate tools for application

Utilize tools such as squeegees or application rollers to smooth out the vinyl during the application process. This helps remove any air bubbles and ensures proper adherence to the surface.

8. Allow proper drying and curing time

After printing and application, allow the printed vinyl to dry and cure according to the manufacturer’s instructions. This will ensure that the adhesive sets properly and the print becomes durable.

9. Handle with care during installation

When installing the printed vinyl, handle it gently to prevent any stretching, tearing, or misalignment. Take your time to position it accurately before applying pressure for firm adhesion.

10. Follow maintenance instructions

If the vinyl requires any specific maintenance or cleaning, follow the recommended guidelines provided by the manufacturer. This will help prolong the lifespan and appearance of the print.

Remember to refer to the specific instructions provided by the manufacturer of the eco solvent printable self adhesive vinyl roll you are using, as different products may have unique operating requirements.

Longevity and Durability of Prints on Eco Solvent Printable Self Adhesive Vinyl Roll

Prints on eco solvent printable self-adhesive vinyl rolls are known for their excellent longevity and durability. Here are some key points to consider:

- Fade Resistance: Eco solvent inks used in the printing process are highly resistant to fading. This ensures that the vibrant colors and sharp details of your prints will remain intact for an extended period.

- UV Resistance: Eco solvent printable self-adhesive vinyl rolls are designed to withstand exposure to UV rays without significant color degradation. This feature makes them ideal for outdoor applications where prints are subjected to sunlight.

- Water Resistance: The vinyl material used in these rolls is water-resistant, which means that the prints are protected from moisture damage. This feature is particularly important for applications such as outdoor signage or vehicle wraps.

- Scratch and Abrasion Resistance: Prints on eco solvent printable self-adhesive vinyl rolls exhibit excellent resistance to scratches and abrasions. This durability ensures that your prints will maintain their quality even in high-traffic areas or when subjected to rough handling.

- Chemical Resistance: The prints are also resistant to common chemicals, making them suitable for applications in environments where exposure to solvents or cleaning agents is expected.

- Longevity: When properly maintained and installed, prints on eco solvent printable self-adhesive vinyl rolls can last for several years. The exact lifespan depends on factors such as exposure to UV light, weather conditions, and the quality of the vinyl and ink used.

It’s important to note that while prints on eco solvent printable self-adhesive vinyl rolls are highly durable, proper installation, cleaning, and maintenance play crucial roles in maximizing their lifespan. Following manufacturer guidelines and best practices will help ensure the longevity of your prints.

Final Words

In conclusion, embracing the eco solvent printable self-adhesive vinyl roll for your printing needs is not only a responsible choice but also a visually stunning one. By opting for this sustainable printing solution, you can enjoy the benefits of vibrant and long-lasting prints while minimizing your environmental impact. The durability of prints on eco solvent printable self-adhesive vinyl roll ensures that your designs will withstand the test of time, resisting fading, UV exposure, water damage, scratches, and chemicals. Whether you’re creating eye-catching signage, engaging advertising materials, or personalized decorations, this versatile medium offers endless possibilities. So, make the conscious decision to print responsibly and adhere beautifully with eco solvent printable self-adhesive vinyl roll, and let your creativity flourish while contributing to a greener future.