Key Features to Look for in a Commercial Vinyl Cutter

Here are the key features to look for in a commercial vinyl cutter:

1. Cutting Width and Length Capabilities:

– Adjustable Cutting Width: A good commercial vinyl cutter should allow you to adjust the cutting width to accommodate different materials and projects.

– Long Cutting Length: Look for a machine that can handle long rolls of vinyl without having to constantly reload the material.

2. Cutting Force and Speed Options:

– Variable Cutting Force: This feature allows you to adjust the pressure applied by the cutter, which is crucial for cutting different types of materials accurately.

– Adjustable Cutting Speed: Being able to control the cutting speed allows for precision and efficiency, especially for intricate designs.

3. Software Compatibility and Ease of Use:

– Compatible Design Software: Ensure that the cutter is compatible with popular design software like Adobe Illustrator, CorelDRAW, or specialized vinyl cutting software.

– User-Friendly Interface: Look for a machine with an intuitive and easy-to-use control panel or software interface. This is especially important for beginners.

– Plug-and-Play Setup: A cutter with a straightforward setup process can save time and frustration during installation.

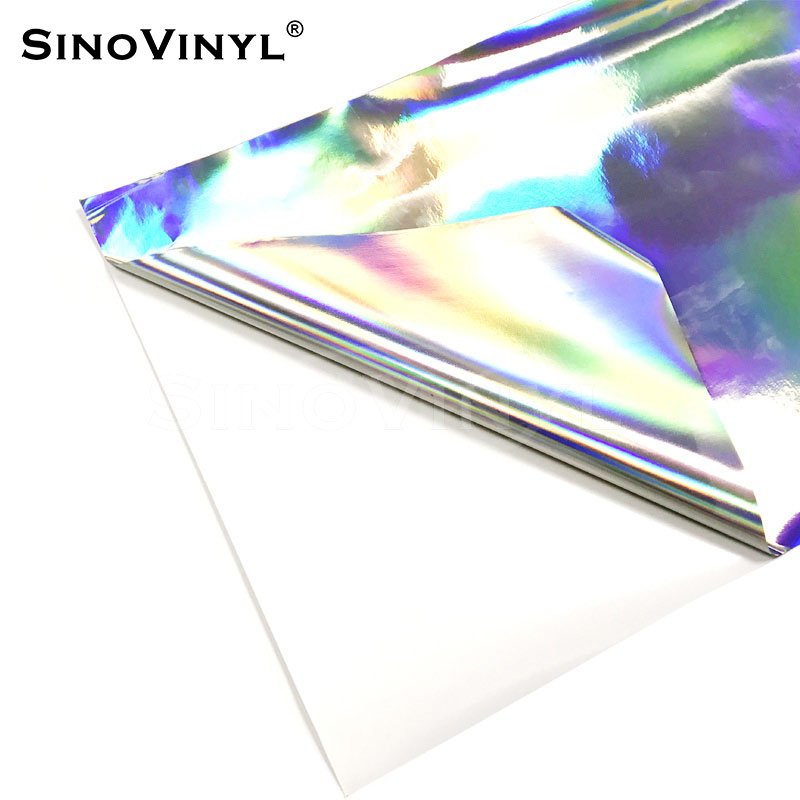

4. Material Compatibility:

– Versatility in Material Types: A good commercial vinyl cutter should be able to handle a wide range of materials, including vinyl, heat transfer vinyl (HTV), cardstock, fabric, and more.

– Adjustable Cutting Depth: Some materials may require a different cutting depth, so having this flexibility is beneficial.

5. Precision and Accuracy:

– High-Resolution Cutting: Look for a cutter with high DPI (dots per inch) capabilities for intricate and detailed designs.

– Tracking and Alignment Systems: Features like optical sensors or laser guides help ensure accurate tracking and alignment of the material.

6. Integrated Print-and-Cut Capabilities (Optional):

– Print-and-Cut Registration: If you plan to print designs before cutting them, consider a cutter with registration marks recognition for accurate alignment.

7. Cutting Speed and Noise Level:

– Balanced Speed: A good cutter should provide a balance between speed and precision, ensuring efficient operation without compromising quality.

– Low Noise Level: Especially important in shared workspaces, a quieter machine can be a valuable feature.

8. Connectivity and Port Options:

– USB and Bluetooth Connectivity: Ensure the cutter can connect to your computer using standard USB ports, and some models offer wireless Bluetooth connectivity for added convenience.

9. Built-In Memory and Storage:

– Internal Memory: Having onboard memory allows you to store and recall designs directly from the machine, reducing the need for constant connection to a computer.

10. Warranty and Customer Support:

– Manufacturer’s Warranty: Look for a machine with a substantial warranty to provide peace of mind in case of any technical issues.

– Reputable Customer Support: Check the manufacturer’s reputation for customer service and support to ensure you can get assistance if needed.

Remember to consider your specific needs and the type of projects you plan to undertake when evaluating these features to find the best commercial vinyl cutter for your purposes.